- Implement lean manufacturing principles to reduce waste and improve productivity in your business.

- Automate processes with robotics, AI, and machine learning for better accuracy and speed.

- Outsource non-critical tasks to focus on core business operations and reduce overhead costs.

- Use data analytics and empower your employees for informed decisions and a motivated workforce.

In the automotive parts manufacturing industry, the competition is fierce, and every business wants to increase its efficiency to gain an edge over the competition. Improving efficiency means improving processes, reducing costs, and increasing productivity, which ultimately translates into higher profits. This blog post will share some tips on becoming more efficient in your automotive parts manufacturing business.

1. Implement Lean Manufacturing Principles

Implementing lean manufacturing principles is the first and most crucial step to becoming more efficient in your manufacturing business. This means following a systematic approach to identify and eliminate waste in every process, from procurement to production to delivery. By reducing waste, you can increase quality, productivity, and profitability.

Lean manufacturing includes the following tools:

a. Value stream mapping

This is a process of mapping out the entire flow of your production from start to finish and identifying areas where processes can be improved. When value stream mapping is done well, it can help to optimize the production cycle and reduce lead times.

b. 5S System

The 5S system is a set of principles that you can use to drive efficiency, improve safety, and reduce waste in the workplace. The 5S system includes Sort, Set in Order, Shine, Standardize, and Sustain.

c. Kaizen

Kaizen is a Japanese philosophy of making tiny yet meaningful modifications to your processes that can bring about tremendous improvements in effectiveness and output. This concept of “continuous improvement” has proven to be incredibly successful for many businesses around the world.

d. Six Sigma

Another tool that can help you become more efficient in your automotive parts manufacturing business is Six Sigma. This data-driven approach to quality control focuses on reducing defects and variation in processes.

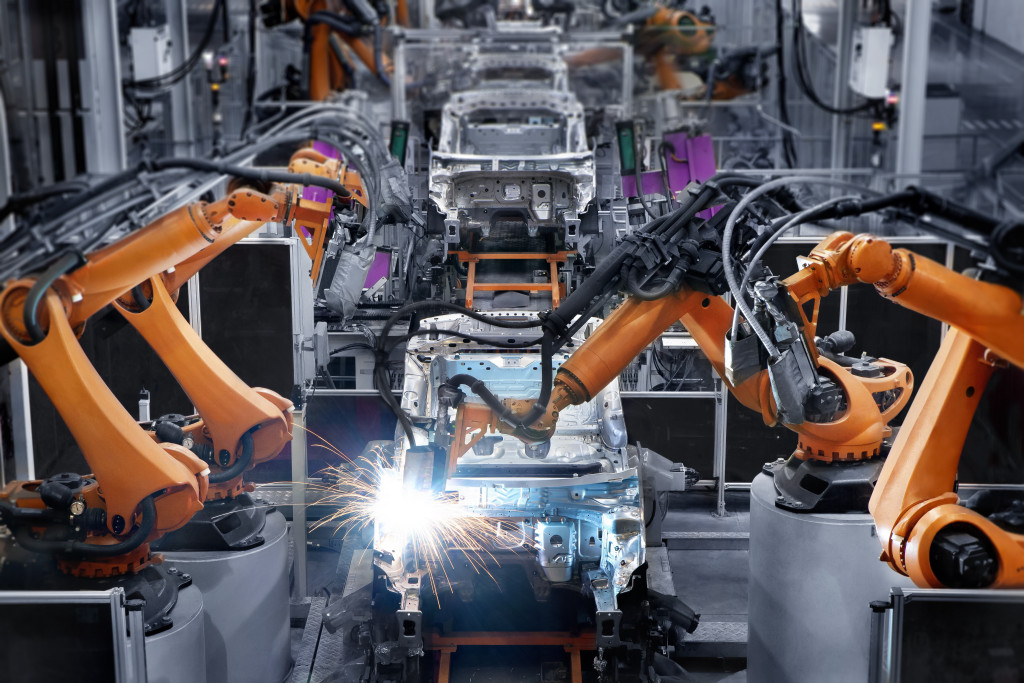

2. Automate Your Processes

Automating your processes means using technology to do jobs that were previously done manually. This includes using automation tools like robotics, artificial intelligence, and machine learning to perform repetitive and time-consuming tasks. By automating your processes, you can reduce errors, speed up production, and enable your workforce to focus on more critical tasks that require creativity and decision-making skills.

You can also use technology to improve accuracy. For example, using electric actuators in control systems can help you improve accuracy and repeatability in your production process. This can result in higher-quality parts and enhanced customer satisfaction. They also help reduce costs and waste compared to manual methods.

3. Outsource Some Tasks

Outsourcing non-core tasks like logistics, packaging, and maintenance can help you focus on your core business and increase efficiency. Instead of investing time and money in these activities, you can delegate them to specialized companies that perform them more efficiently and cost-effectively. This way, you can reduce your overhead costs and increase your productivity. Choose reputable outsourcing partners that can meet your quality and delivery expectations.

4. Use Data Analytics

Data analytics can be a powerful tool to increase efficiency by providing insights into your production processes, customer needs, and market trends. By collecting, analyzing, and interpreting data, you can identify patterns and trends to help you make better decisions, optimize your processes, and create products that better meet your customers’ needs.

Use data analytics tools like business intelligence software, data visualization tools, and predictive analytics to gain a competitive advantage. These tools can help you better understand customer behavior and predict future demand, enabling you to make informed decisions about pricing, resources, and production.

5. Empower Your Employees

Finally, to become more efficient, you need to empower your employees. This means providing them with the tools, resources, and training they need to do their jobs effectively. You also need to create a culture of continuous improvement, where employees are encouraged to identify and solve problems, share ideas, and take ownership of their work. Empowering your employees can create a motivated and engaged workforce willing to go the extra mile to achieve your business goals.

Becoming more efficient in your automotive parts manufacturing business is crucial to stay competitive and profitable in today’s market. By implementing lean manufacturing principles, automating your processes, outsourcing some tasks, using data analytics, and empowering your employees, you can improve your processes, reduce costs, and increase productivity. These tips are just the beginning, and you should always look for ways to improve and innovate your business. Remember to involve your employees in the improvement process and keep an open mind to change. You can create a more efficient and successful automotive parts manufacturing business with the right mindset and tools.